Cleanroom garments as a system

Even the best cleanroom garments can cause problems if not all parameters that can influence the so-called garment system are coordinated.

- First of all, the material properties should be defined with regard to the customer requirements. Technical requirements such as high particle retention (impermeability) and employee concerns like wearing comfort (high breathability) must be coordinated.

- In addition, the selection and definition of equipment and special accessories such as zippers, pockets, etc. must be taken into account.

- The ambient conditions in the respective cleanrooms in which the garments are to be used also play a role. First of all, temperature and humidity must be mentioned here.

- Special requirements at the workplace, e. g. special requirements from the field of PPE (Personal Protective Equipment), must be taken into account when defining a clothing system, if necessary.

- The professional decontamination or cleaning of the clothing is an essential part of a functioning clothing system.

- Employee training is also one of the important features of an appropriate system.

Variety of models

Dastex can fall back on several 1,000 models or model variants. Individual solutions are therefore no more a problem than standardised models. The production of special sizes and the joint development of new articles are also part of our daily tasks.

For each model, the basic version is described on the website. You will also find an overview of other possible equipment. It often turns out in practice that certain details in the work/production process place special demands on cleanroom garments and therefore standard models are out of the question or at least need to be modified. It may well be that other users have already had similar questions and we have already found a solution. Dastex offers the possibility to develop and implement such individual solutions together. The models listed in the product portfolio represent only an extract of the already existing concepts and may help you to find a solution for your special requirements. The complete range of models and variants cannot be shown due to the number of variants.

In order to provide our customers with the greatest possible flexibility when defining their clothing system, in many cases - as in a modular system - a free choice can be made between standard options and special accessories.

However, if you are interested in individual solutions or ideas that you would like to implement with us, we look forward to hearing from you.

Filter between human and product

Despite technical progress, people in cleanrooms are still considered one of the greatest sources of contamination. This applies both to particulate contamination and microbiological contamination. Only if the product is completely decoupled from humans, e.g. by using isolators or Small Mechanical InterFace technology (mini-environments), the above statement no longer applies. For all other areas of application, it can be assumed that approx. 30 – 40% of the contamination in the cleanroom could well originate from the employees.

Our test results (extensive study carried out in Dastex's own Body-Box test cabin) confirm the above statements and give first indications of the particle and germ counts that can be expected from people and their clothing.

Airborne particle and germ emission by humans

Measurements in the body box available at Dastex provide information on how many particles people can emit in different garment systems during different movement sequences. The test results illustrate the important role that the right garment system plays. If the employee wears over his or her private clothing (in this case simulated by a pair of trousers and a sweater made of 100% cotton) an overall, a hood and overboots, the particle emission is reduced to 0.2 – 0.3% of the initial level.

The quality of the fabrics is one thing. But the workmanship and the fit must also be right in order to create a reliable barrier between the particle sources and the cleanroom, which is accepted by the employees. Find out more about wearing comfort and acceptance in our study.

Manufacturing quality

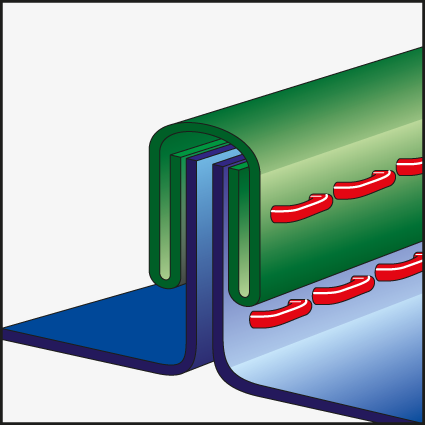

For our cleanroom garments, we mostly use the piped seam (with edging tape) as a closing seam. This means that the two fabric edges are edged with a polyester tape and joined by an additional seam. This reduces the risk of a seam opening unnoticed and particles escaping uncontrolled to a minimum.

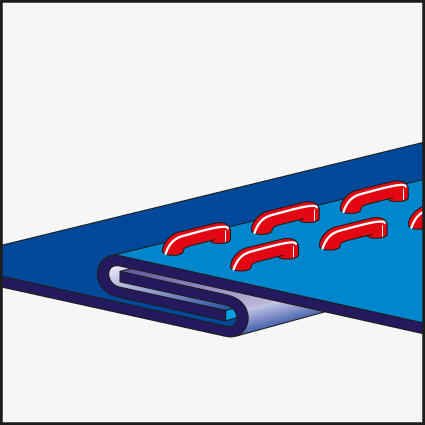

As an option, we also offer the felled seam for all products, which is also suitable for cleanroom garments.

For additional process requirements from the ESD area (conductivity), Dastex offers its customers a wide range of different solutions (see Cleanroom garments / ESD Overalls and ESD-Lab coats).

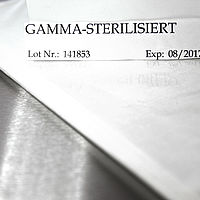

Dastex cleanroom garments are decontaminable and sterilizable (autoclavable up to 134 °C as well as gamma sterilisable). Thereby a shrinkage of the clothing within usual tolerances is possible. As certain garment elements (e.g. zippers) have to be adapted to the sterilisation process used, we will be pleased to advise you before placing your order.

Size allocation

These figures are based on experience and are not binding. We will be pleased to provide you with samples to check the accuracy of fit.

For many models the standard sizes 3EL/3XL and 4EL/4XL are also available. In the event that no size from the size set fits, we can make dimensional changes or adapt them individually.

Special dimensions for cleanroom garments/ undergarments

In addition to the standard sizes/dimensions, there is also the possibility of having garments made individually. However, the aim of special sizes should be to remain as close as possible to standard sizes in order to ensure reproducibility on the one hand and to keep the additional costs involved as low as possible on the other. A typical example from practice would be a coverall with the standard size L but with the leg length shortened by 10 cm and the arm length shortened by 5 cm.

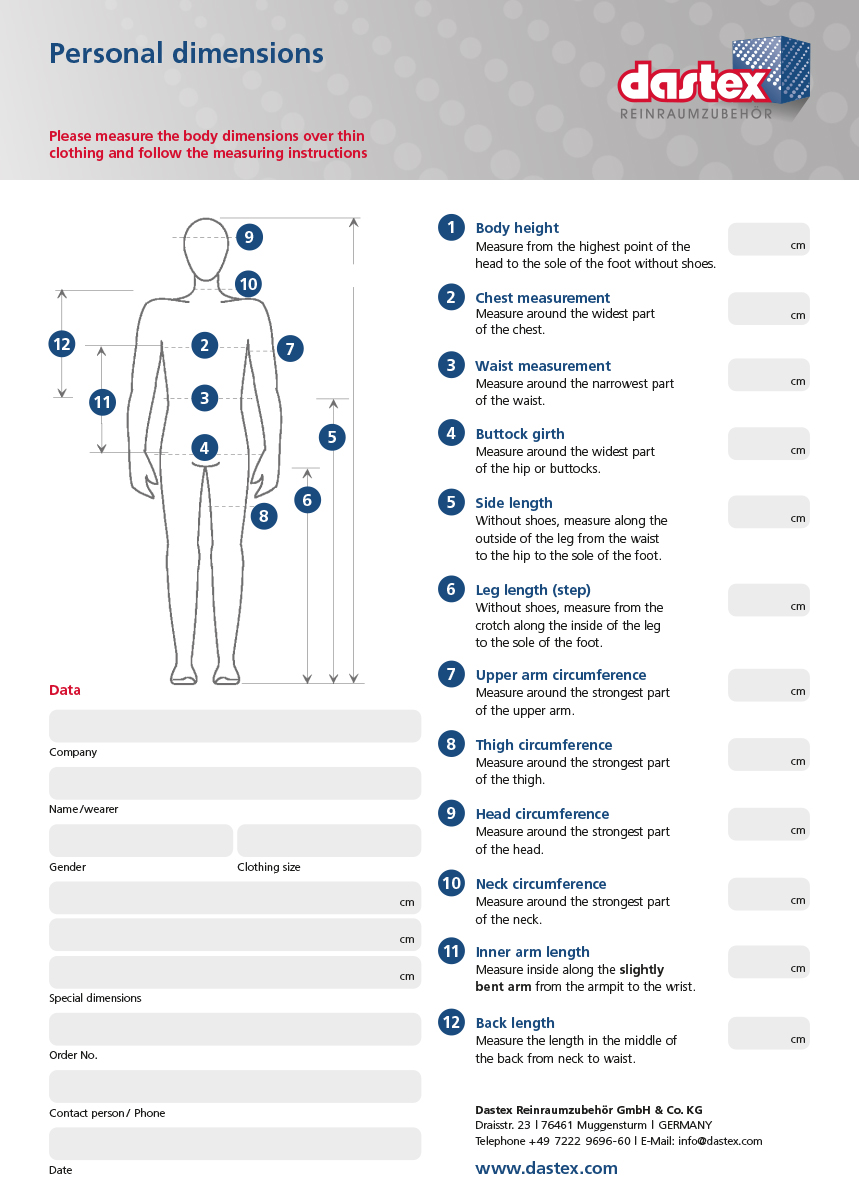

More complex and therefore also associated with higher costs are special sizes where the cutting templates have to be adapted to a much greater extent. For this purpose, Dastex offers you a form to record the body measurements of the person concerned. Thereupon we first produce a release sample before the actually required (complete) number of garments is produced for this person.

On the right side you can download the form "Personal dimensions" to determine the dimensions.