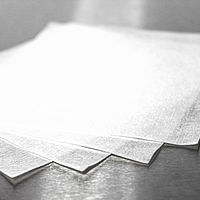

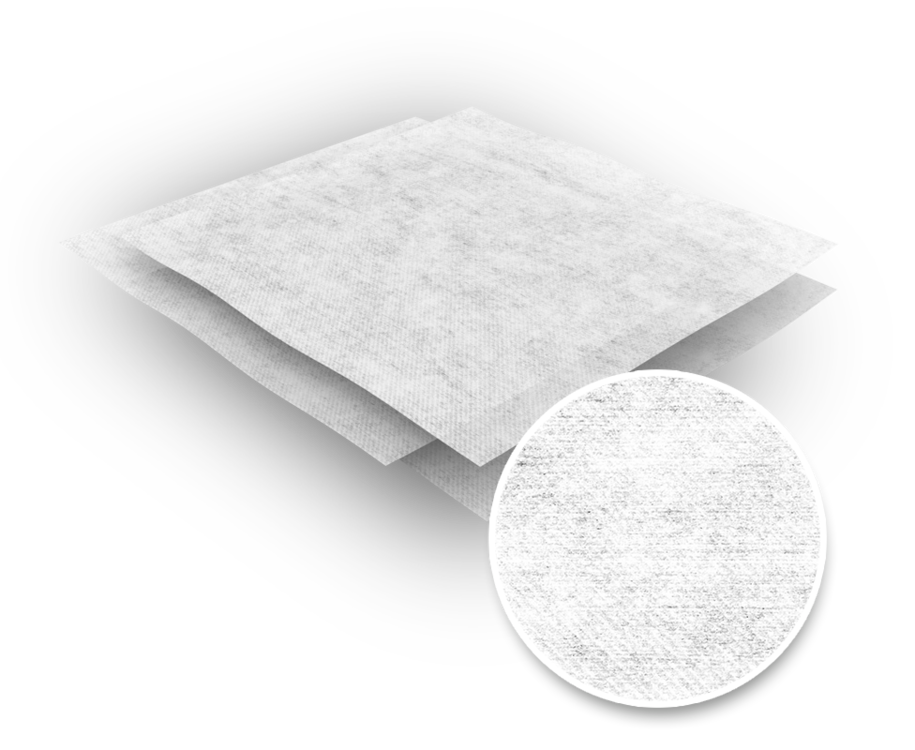

The gamma irradiated version of the series 303, a polyester-cellulose non-woven wipe, is versatile, both in microbiological controlled areas and in purely particle controlled areas. The special surface in the form of a twill structure (similar to ribs) also serves to absorb slightly coarser impurities, which can become trapped between the ribs. Although made of a non-woven fabric, the wipe has a certain abrasion and tear resistance (even when damp).

The cloth material combines the different strengths of cellulose (➜ absorbency) and polyester fibre (➜ abrasion resistance) and is therefore also a „happy medium“ in terms of cost.

Facts

Polyester-cellulose

Non-woven, 45% PES / 55% CEL, hydroentangled, twill-like, gamma irradiated

Properties

- 45% polyester / 55% cellulose

- hydro-entangled non-woven fabric

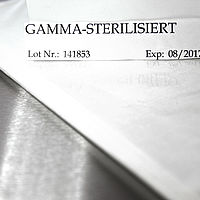

- gamma-irradiated

- low particle and fibre emission

- relatively abrasion resistant

- special twill-textured surface

- good absorptive capacity

- double bag packing

Advantages

- good chemical compatibility with different solvents and cleaning agents

- multipurpose

- can also absorb slightly coarser impurities due to the special surface, without damaging the surface to be cleaned.

- cost-effective

Applications

- all-purpose wipe

- absorbency of liquids and spills

- suitable for cleaning tools

- workplace cleaning – especially for smooth surfaces

Product recommendation based on cleanroom classes

Of course, cleanroom wipes used in ISO 5 can also be used in ISO 9, but in this case the economic efficiency and usefulness should be considered.

A 1 to 1 allocation of cleanroom wipes to an air cleanliness class according to ISO 14644-1 is not possible. Recommendations can only be made on the basis of special properties relevant from a cleanroom technical point of view, such as "abrasion resistance" or "particle emission". Users can find further information on this in VDI Guideline 2083 Part 9.2.

Technical data

| Properties | Unit of measurement | Value | Test method | |

|---|---|---|---|---|

| Material | 45% PES / 55% CEL | |||

| Edge processing | cold cut | |||

| Mass per unit area | g/m2 | 68 | ||

| Thickness |

mils mm |

19 0,48 | ||

|

Absorption capacity (Ai) intrinsic (Ae) extrinsic | ml/g ml/m2 | 4.9 328 | IEST-RP-CC004.3 | |

|

NVR Non-volatile residues |

IPA based DI water based |

mg/g mg/g |

0.020 0.016 | IEST-RP-CC004.3 |

| Particulate residues |

0.5 – ≤ 5.0 µm > 5.0 – ≤ 100 µm |

x 106/m2 x 106/m2 |

304 15 |

IEST-RP-CC004.3 Section 6.1.3 Biaxial Shake Test |

| Fibre residues | > 100 µm | fibres/m2 | 111,000 |

IEST-RP-CC004.3 Section 6.2.2.2 |

| Ionic residues |

Sodium (Na+) Chloride (ClO2-) |

ppm ppm |

52 30 |

IEST-RP-CC004.3 Section 7.2.2.1 |

| Organic contaminants |

silicone oil amides D-n-octylphthalate (DOP) |

n. s. n. s. n. s. |

by FTIR spectrometer Fourier transform infrared spectrometer | |

| Sterilisation | Gamma radiation | kGy | 25 – 40 | DIN EN ISO 11137-1 |

| Dimensions | PU per bag | Art. No. | ||

|

9" x 9" (~ 23 x 23 cm) 12" x 12" (~ 30 x 30 cm) |

300 pcs. double packed 150 pcs. double packed |

57303 0909 57303 1212 | ||

| n. s. = not specified n. d. = not detectable |

Note