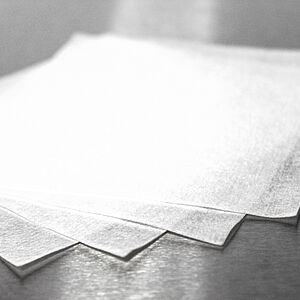

The wipe Bemcot™ M-3 II from Asahi KASEI is made of an outstanding cupro-cellulose spunbound non-woven fabric. It has a very good absorption capacity and a strong resistance to most cleanroom chemicals. It is free of adhesives and binders and is extremely lint-free. The Bemcot™ M-3 II is the perfect wipe for the CD or DVD industry.

Facts

Cellulose

Non-woven, 100% CEL (Cupro)

Properties

- 100% cellulose

- non-woven fabric (Bemliese™)

- free from adhesives and binders

- 4-folded

- packed in a PE bag

Advantages

- high absorbency in relation to the mass per unit area

- especially low lint

- electrostatic neutral

- low particle abrasion

- antistatic

- heat resistant (min. 250°C)

- biologically degradable

Applications

- cleaning of scratch-sensitive surfaces

- ideally suited for CD and DVD production

- damp wiping with solvents

Product recommendation based on cleanroom classes

Of course, cleanroom wipes used in ISO 5 can also be used in ISO 9, but in this case the economic efficiency and usefulness should be considered.

A 1 to 1 allocation of cleanroom wipes to an air cleanliness class according to ISO 14644-1 is not possible. Recommendations can only be made on the basis of special properties relevant from a cleanroom technical point of view, such as "abrasion resistance" or "particle emission". Users can find further information on this in VDI Guideline 2083 Part 9.2.

Technical data

| Properties | Unit of measurement | Value | Test method | |

|---|---|---|---|---|

| Material | 100% CEL (Cupro) | |||

| Edge processing | cold cut | |||

| Mass per unit area | g/m2 | 30 | ||

|

Absortive capacity (Ai) intrinsic (Ae)extrinsic | ml/g ml/m2 | 9.7 288 |

IEST-RP-CC004.3 Section 8.1 | |

| Absorbency time | second | 1 |

IEST-RP-CC004.3 Section 8.2 | |

|

NVR Non-volatile residues |

IPA based DI water based |

g/m2 g/m2 |

0.006 0.06 |

IEST-RP-CC004.3 Section 7.1.2 |

| Particle residues | ≥ 0.5 µm | x 106/m2 | 110 |

IEST-RP-CC004.3 Section 5.1 |

| Fibre residues | > 100 µm | x 103/m2 | 12 |

IEST-RP-CC004.3 Section 5.2 |

| Ionic residues |

Sodium (Na+) Chloride (ClO2-) |

ppm ppm |

49 1 |

IEST-RP-CC004.3 Section 7.2.2 |

| Organic contaminants |

silicone oil amides D-n-octylphthalate (DOP) |

n. s. n. s. n. s. |

by FTIR spectrometer Fourier transform infrared spectrometer | |

| Size | PU/Carton | subpacked | Art. No. | |

|

10" x 10" |

3,000 | 30 bags à 100 wipes | 52302M3 | |

| n. s. = not specified n. d. = not detectable |

Note