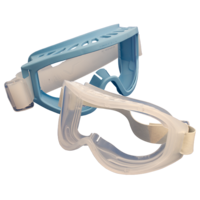

One of the most frequently discussed aspects of a cleanroom clothing system for use in sterile areas is certainly the safety goggles prescribed in the new Annex 1 (EU GMP guidelines). From the point of view of wearing comfort, this is undoubtedly not a boon, but from a cleanroom point of view it is a clothing element that is undisputedly justified.

The fact that beard hairs and hairs on the scalp have to be covered is understandable for everyone, but consequently also the eyelashes and eyebrows together with the corresponding skin areas. From the user's point of view, however, it should be noted that in most cases these protective glasses are very uncomfortable to wear.

Decision criteria:

- fit

- view window (as unrestricted as possible)

- anti-fogging properties of the screen

- no impairment of visual acuity

- ventilation system of the frame

- simple usage

- secure covering of all still open skin areas in the face

On closer inspection, it is noticeable that the last two bullet points are directly related to the protective hood worn. In particular, ensuring that no open areas of skin are visible on the face after the goggles are put on depends equally on the shape of the goggles and the shape of the hood.

This product innovation for the cleanroom industry was nominated for the renowned Red Dot Award and was also selected as the winner. Such a confirmation, to extend a successful product portfolio by innovative variants and thus to facilitate the dressing procedure for the user as well as to meet the necessary requirements and regulations from a quality point of view, will also in future drive Dastex to respond flexibly to customer needs and to implement these in total in innovations.

In terms of manageability, the aim is to provide wearers with solutions that make dressing procedures as simple as possible. At the same time, the residual risk of additional contamination during the dressing procedure should be minimised as far as possible. If, in this context, pressure points on the face can also be reduced, this is a positive side effect.

Dastex has thought about this in detail and has developed a combination of hood and protective goggles that takes the above decision criteria into account. The aim was to be able to offer a solution for almost any combination of hood and goggles.

This means a coordinated headgear with different fields of vision for most common safety eyewear models.

Even if the so-called duck-shape appears unusual and may cause one or the other observer to smile, all necessary aspects have been incorporated into this development in order to reconcile cleanroom and wearing comfort requirements. Of course, other hood models are also possible, as shown opposite.

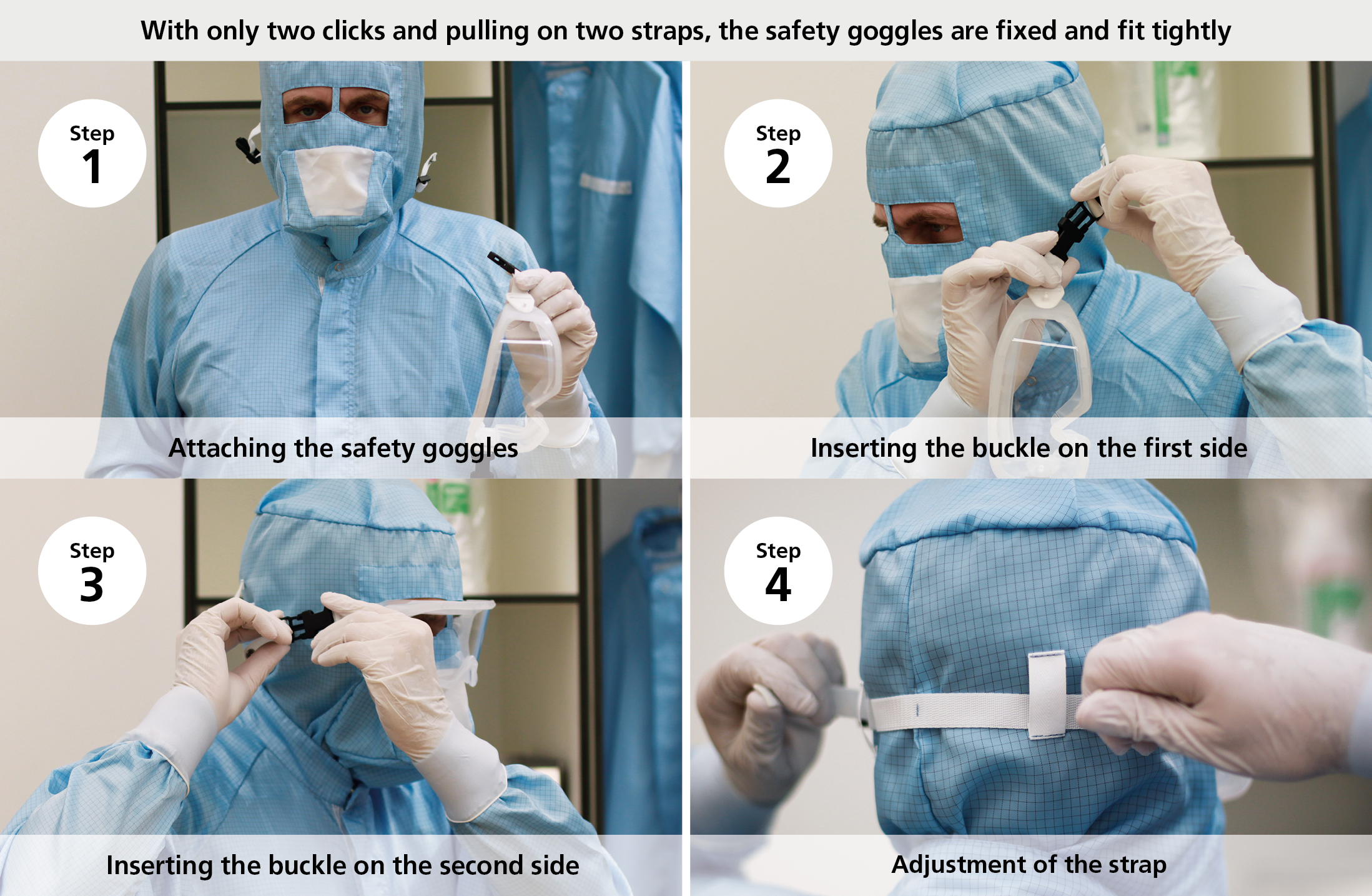

The decisive factor, however, is the simple handling that can be adapted to many hoods. With only two "clicks" and pulling on two straps, the goggles fit tightly and at the same time the circumference of the hood is fixed accordingly. This process is shown in the adjacent picture.

Elastic bands, which often press or slip, with the consequence that the wearer has to touch the hood and goggles again, are replaced with this user-friendly solution. Since the goggles are always one of the last parts of a cleanroom garment system to be put on before entering the cleanroom, handling with buckles and straps is easy, even when fully dressed.